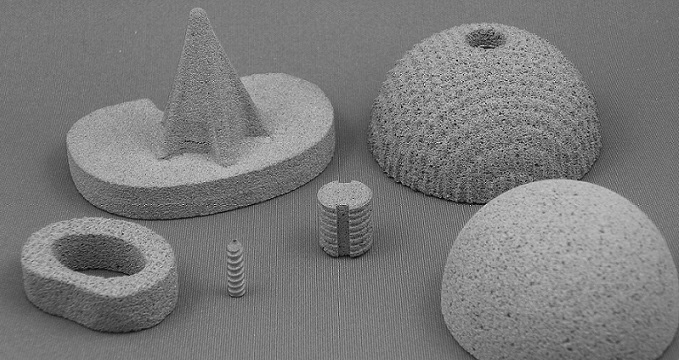

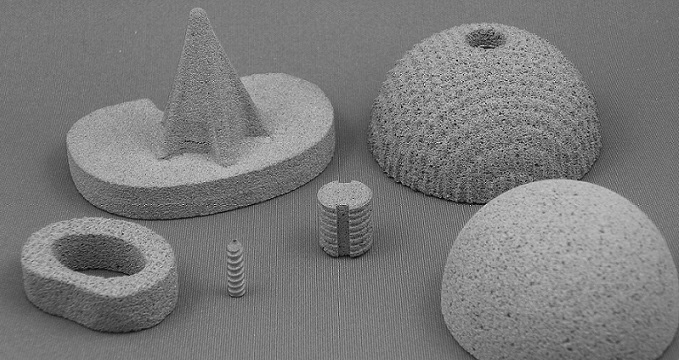

Hot Isostatic Pressing (HIP)

This process is used to produce full density parts with great mechanical properties even with the finest materials.

This process is used to produce full density parts with great mechanical properties even with the finest materials.